Kerry Deare spends the winter ashore in New Jersey, and that usually means a few months of rough weather and snow. Over the years we have stored the boat both afloat and on land. In the past when storing on land we usually unstepped the mast each season and then by using the mast as a ridge pole and plastic tubing (HDPE irrigation pipe) for support, we covered the boat with a standard canvas tarp. The pros and cons about storing on land with mast stepped could fill many pages and I won't cover that subject. However in recent years with radar and other electronic gear now mounted on the backstay, unstepping the mast in fall and then stepping the mast and rewiring all the electronics in spring is impractical for me. Thus for the last several years we wintered the boat with the mast stepped. Unfortunately devising a good and simple protective cover with this arrangement evolves into a small but challenging engineering project. There have been several wrong turns along the way, but each winter we get closer to where we'd like to be.

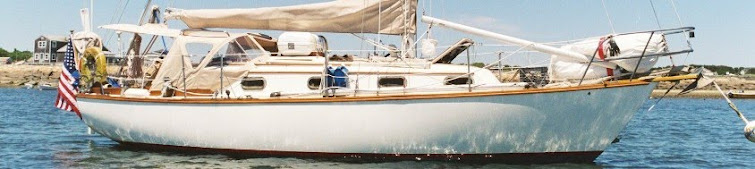

Kerry Deare spends the winter ashore in New Jersey, and that usually means a few months of rough weather and snow. Over the years we have stored the boat both afloat and on land. In the past when storing on land we usually unstepped the mast each season and then by using the mast as a ridge pole and plastic tubing (HDPE irrigation pipe) for support, we covered the boat with a standard canvas tarp. The pros and cons about storing on land with mast stepped could fill many pages and I won't cover that subject. However in recent years with radar and other electronic gear now mounted on the backstay, unstepping the mast in fall and then stepping the mast and rewiring all the electronics in spring is impractical for me. Thus for the last several years we wintered the boat with the mast stepped. Unfortunately devising a good and simple protective cover with this arrangement evolves into a small but challenging engineering project. There have been several wrong turns along the way, but each winter we get closer to where we'd like to be. The current frame system is based on the boat's small spars and standard flexible HDPE irrigation pipe (photo above). It seems to work well without too much fuss and expense, and it's easily set up and dismantled each year. We use the spinnaker pole as a "ridge" forward of the mast, and the adjustable whisker pole abaft the mast. We then fit the HDPE irrigation pipe at 6 locations using the lifeline stanchions and other parts of the deck to secure each piece loop. When finished, the frame system resembles a Conestoga wagon and usually generates a range of comments form the pros at the boatyard. Yet in the final tally it's both inexpensive and surprisingly sturdy. At our yard we're able to do most of the winterization while afloat, and we usually set up the frame while the boat is in the water to avoid climbing up and down the ladder. Once the boat is hauled and cleaned (photo right), we can fit the cover without much fuss.

The current frame system is based on the boat's small spars and standard flexible HDPE irrigation pipe (photo above). It seems to work well without too much fuss and expense, and it's easily set up and dismantled each year. We use the spinnaker pole as a "ridge" forward of the mast, and the adjustable whisker pole abaft the mast. We then fit the HDPE irrigation pipe at 6 locations using the lifeline stanchions and other parts of the deck to secure each piece loop. When finished, the frame system resembles a Conestoga wagon and usually generates a range of comments form the pros at the boatyard. Yet in the final tally it's both inexpensive and surprisingly sturdy. At our yard we're able to do most of the winterization while afloat, and we usually set up the frame while the boat is in the water to avoid climbing up and down the ladder. Once the boat is hauled and cleaned (photo right), we can fit the cover without much fuss.

For the first several winters using the current frame system we tried to fit standard rectangular plastic tarps around the standing rigging, but after several attempts we concluded that "simple" wasn't necessarily "better" when it comes to boat covers. Finally last winter we made a first pass at tailoring the standard blue plastic tarps to fit around the standing rigging more effectively. After much measuring, guessing, inhaling contact cement fumes, swearing, and zipping through a lifetime supply of expensive and exotic tapes, we obtained a reasonable first approximation that got us through the cold season. Prior to fitting the tailored cover once again this year, we made a few changes based on last year's results to get a better fit. The results are shown in the photos at left and at right above. This project, like most, is ongoing and no doubt there will be changes next time. It appears that building a winter cover follows the usual pattern observed on other boat projects: the third time is the trick.

For the first several winters using the current frame system we tried to fit standard rectangular plastic tarps around the standing rigging, but after several attempts we concluded that "simple" wasn't necessarily "better" when it comes to boat covers. Finally last winter we made a first pass at tailoring the standard blue plastic tarps to fit around the standing rigging more effectively. After much measuring, guessing, inhaling contact cement fumes, swearing, and zipping through a lifetime supply of expensive and exotic tapes, we obtained a reasonable first approximation that got us through the cold season. Prior to fitting the tailored cover once again this year, we made a few changes based on last year's results to get a better fit. The results are shown in the photos at left and at right above. This project, like most, is ongoing and no doubt there will be changes next time. It appears that building a winter cover follows the usual pattern observed on other boat projects: the third time is the trick. There are several obvious places where a little tailoring helps to make a better job. Around the port and starboard shrouds it is usually difficult to both keep the weather out, and get a decent fit. Therefore we added heavily reinforced cuts port and starboard that can be laced around the shrouds (photo at left). The forward cover containing these slits is also cut to fit around the mast as well as around the headstay, and then secured by lacing. The reason for lacing instead of taping is that if the tape is sufficiently good to last during the winter, there is no simple method to remove the tape and at the same time not destroy the cover material itself. In each instance where cutting the tarp was required, we reinforced the area in question with several layers of blue tarp material and used a standard grommet tool to fit the lacing. The after cover is cut to fit around the backstay and the radar mount in a similar fashion.

There are several obvious places where a little tailoring helps to make a better job. Around the port and starboard shrouds it is usually difficult to both keep the weather out, and get a decent fit. Therefore we added heavily reinforced cuts port and starboard that can be laced around the shrouds (photo at left). The forward cover containing these slits is also cut to fit around the mast as well as around the headstay, and then secured by lacing. The reason for lacing instead of taping is that if the tape is sufficiently good to last during the winter, there is no simple method to remove the tape and at the same time not destroy the cover material itself. In each instance where cutting the tarp was required, we reinforced the area in question with several layers of blue tarp material and used a standard grommet tool to fit the lacing. The after cover is cut to fit around the backstay and the radar mount in a similar fashion.

To reduce wear and tear on the cover during the winter, we fitted a roll-up door on the port side. The door allows easy access for winter work without the need to dismantle a part of the cover itself. Last fall prior to fitting the cover for the first time, we carefully measured for the door. While actually building the cover and fitting the door at home, we decided it just didn't look right and made some changes "on the fly." Of course it happened that the original measurements were indeed correct and my "eyeball" modifications were not. Prior to installing the cover again this winter we "uncorrected" to get back to where we should have been in the first place. The benefit is that it's much easier to get the old man's bones up the ladder and onto the boat now.

To reduce wear and tear on the cover during the winter, we fitted a roll-up door on the port side. The door allows easy access for winter work without the need to dismantle a part of the cover itself. Last fall prior to fitting the cover for the first time, we carefully measured for the door. While actually building the cover and fitting the door at home, we decided it just didn't look right and made some changes "on the fly." Of course it happened that the original measurements were indeed correct and my "eyeball" modifications were not. Prior to installing the cover again this winter we "uncorrected" to get back to where we should have been in the first place. The benefit is that it's much easier to get the old man's bones up the ladder and onto the boat now.The nice part about the present system is that going down to the boatyard for a few hours work is really much less bother. The side door makes going on board less complex, and the dark color of the cover itself provides something akin to a "greenhouse" effect, making the area under the cover quite comfortable once the sun has been up for a few hours. The frame ridge poles and tubing are sufficiently high so that there's plenty of room to work on deck without gymnastics during the winter.

%40-01+016a.jpg)

Thanks Armond! Good stuff, I bought some today and it looks promising.

ReplyDeleteLast year worked out okay, but I think some upgrades are in order. I'll keep you posted.

BTW, you do know your exploits have made you something of a cult hero in South Philly sailing circles, don't you? We were talking about trading cards at the yard today but no one can seem to find a photo of you . . . P-)

Best,

MFC